As the demand for electric vehicles (EVs) continues to rise, transporting electric car batteries is becoming a crucial consideration for businesses. The logistics of safely and efficiently transporting new, used, end-of-life and even damaged EV batteries through the supply chain can be a complex and tightly regulated process.

Mishandling these high-voltage, energy-dense power sources during transportation poses significant risks. To ensure the safety of EV battery transportation, it's crucial to understand the complexities of this process.

Understanding Electric Car and Lithium-Ion Batteries

The global surge in demand for electric vehicles, portable electronics and renewable energy storage solutions has led to significant growth in the lithium-ion battery industry. This growth is driven by the increasing need for efficient and long-lasting energy storage solutions. Lithium-ion batteries have become the preferred choice for these applications due to their high energy density, long cycle life and relatively light weight. As a result, the industry has experienced a substantial increase in manufacturing activities, with the UK alone generating £245 million in annual market revenue.

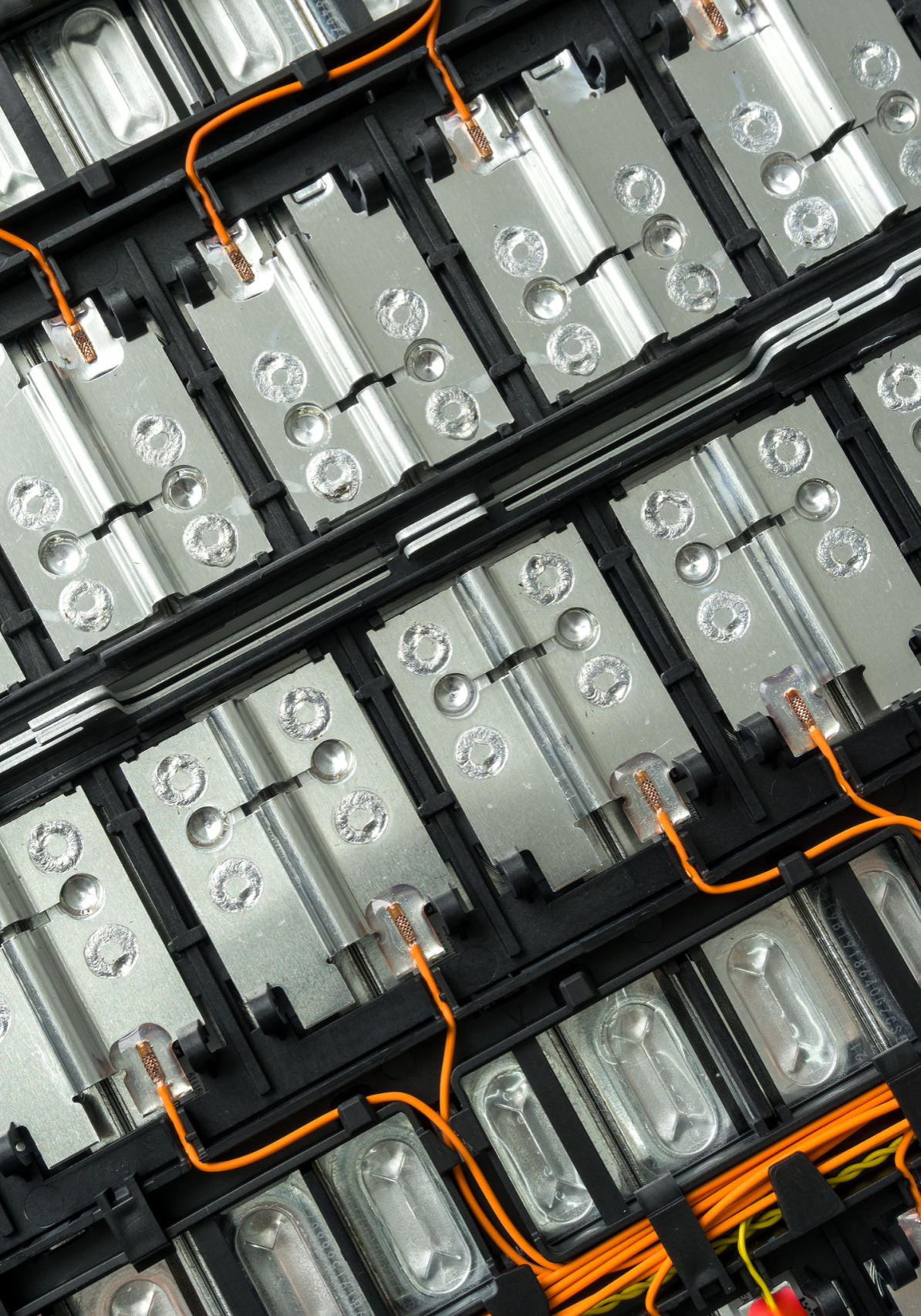

Lithium-ion based EV batteries are pivotal components in the transition towards sustainable transportation. These batteries offer the high energy density required for electric vehicles to achieve adequate driving range while producing no tail-pipe emissions in the final vehicle. Moreover, the decreasing cost of electric-vehicle lithium-ion battery packs has made electric vehicles more affordable, further propelling the demand for these batteries.

Why are EV Batteries Challenging to Transport?

EV battery transportation presents significant logistical and safety challenges due to their size, weight and potential hazards, necessitating specialised handling and adherence to strict regulations.

EV batteries are big, heavy and difficult to handle and ship, often requiring special training and equipment. Moreover, they pose a significant fire risk, leading to their classification as hazardous materials. As such, shipments must comply with hazmat regulations for packaging, labelling, documentation, training and specified shipping methods.

It is important to note that shipping rules and requirements vary by country and transportation mode, adding complexity to the process. Additionally, battery transportation often involves multiple supply chain partners who must be aligned on the processes, equipment and transport instructions.

These factors contribute to the challenges associated with the transportation of EV batteries, underscoring the need for meticulous planning, stringent safety measures and clear communication among all involved parties.

Regulations and Classifications that Apply to EV Battery Transportation

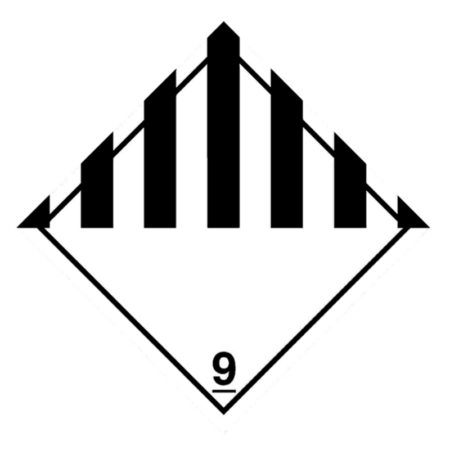

When it comes to transporting electric car batteries, safety considerations are paramount. The regulation and classification of lithium-ion batteries as Class 9 miscellaneous dangerous goods by the United Nations underscore the inherent risks involved. These risks include thermal runaway and potential fires/explosions triggered by overheating, puncturing or electrical faults.

The transport of class 9 hazards is subject to international and national regulations such as the UN Manual of Tests and Criteria, which provides specific requirements for the packaging, labelling and transport of lithium-ion batteries.

Below are the applicable UN Classification Categories for different articles comprising lithium ion batteries:

- UN 3090: lithium metal batteries, including lithium alloy batteries.

- UN 3091: lithium metal batteries contained in equipment or lithium metal batteries packed with equipment, including lithium alloy batteries.

- UN 3480: lithium ion batteries, including lithium ion polymer batteries.

- UN 3481: lithium ion batteries contained in equipment, or lithium ion batteries packed with equipment, including lithium ion polymer batteries.

- UN 3536: lithium batteries installed in cargo transport units, lithium ion batteries or lithium metal batteries.

Packaging and Handling Electric Car Batteries

To ensure the safe and compliant transportation of electric car batteries, specialised and custom packaging that can handle their size and weight and comply with various testing standards, is essential.

Electric car batteries are not only heavy and large but also pose unique safety challenges due to their chemical composition. Therefore, workers need ADR training and special equipment just to handle them.

In addition to the size and weight, shipments of electric car batteries must comply with all hazmat regulations for packaging, labelling, documentation, training and specified shipping methods. This includes stringent adherence to regulations for the transportation of dangerous goods.

Packaging for electric car batteries must be designed to prevent damage during transportation and to mitigate potential hazards such as fire, short-circuiting or leakage of hazardous materials. Furthermore, the packaging should facilitate easy and safe handling during loading and unloading processes.

Given the potential risks associated with electric car batteries, ensuring that the packaging and handling procedures are compliant with all relevant standards is crucial for the safety of workers, the public and the environment.

Environmental Risks

The safe handling and transportation of electric car batteries are critical not only for worker and public safety but also to mitigate potential environmental risks associated with their chemical composition and potential hazards.

Electric car batteries often contain hazardous materials such as lithium, cobalt and nickel, which can pose environmental risks if not handled properly. In the event of a transportation accident or mishandling, these chemicals can leak and contaminate soil and water sources, leading to long-term environmental damage.

The risks are further compounded by the potential for thermal runaway, a chain reaction of battery cell failures that can result in fire and the release of toxic fumes.

Therefore, it is imperative for transportation and logistics professionals to strictly adhere to regulations and best practices for the safe handling and transportation of electric car batteries. Additionally, robust contingency plans and emergency response protocols should be in place to promptly address any incidents and minimise the environmental impact.

Transporting Electric Car Batteries: Choosing the Right Logistics Partner

The transportation of electric car batteries presents unique challenges due to their high energy density and potential environmental risks. Careful consideration and adherence to safety protocols are essential to ensure the safe and efficient transportation of electric car batteries.

At JJX, we take pride in leading the transportation of all nine classes of ADR dangerous goods by road, including the transport of EV batteries.

Our commitment to safety, qualified drivers, temperature-controlled capabilities, compliance with regulations and top-tier supply chain security make us the preferred choice for handling hazardous materials.

We're ready when you need us